Amps should be 86-90amps DCEP. Due to its high nickel content the soft and tough weld metal is especially suitable for welding cast iron which is brittle or old.

Electrodes Used For Ductile Iron Welds Download Table

The weld deposits are hard and are not machine-able but can be finished by grinding.

Welding electrode for grey cast iron. The most common arc welding electrodes for grey cast iron are nickel and nickel-iron types. It is an arc welding process where a solid wire electrode is used through a welding gun. To Heat or not to Heat In general it is preferred to weld cast iron with preheat--and lots of it.

The electrode is ideal for welding machine bases engine blocks gears Pumps Joining of broken cast iron parts for repairing defects in foundry castings. But another way to successfully weld cast iron is to keep it cool--not cold but cool. We ship worldwideCall us.

Brazing isnt really welding as it doesnt fuse the metal as a weld does. MIG stands for metal inert gas. Cast iron and steel electrodes must be used with high preheats 550C to prevent cracking and the formation of hard deposits.

Oxy-acetylene welding is another option frequently used to weld cast iron. This is the lowest cost electrode for welding cast iron and the electrode has a very user-friendly arc. Ad We supply Monel 400 60 Inconel 112 welding rods filler wire.

Suitable for welding joints as well as for surfacing of worn cast iron parts. Before starting the welding process with cast-iron electrodes you will need to pre-heat the flaps base material because cast-iron becomes unstable at a temperature between 149 and 500 Fahrenheit degrees and so it might create cracks on the welding seams during the cooling phase. These electrodes have been used with or without preheating andor post weld heat treatment.

Ad We supply Monel 400 60 Inconel 112 welding rods filler wire. As mentioned earlier regarding the graphite flakes due to graphite chances of slag inclusion is higher. For welds where machining is not required and where the weld is expected to rust like the cast iron Lincoln Ferroweld stick electrode can be used.

MIG welding is a popular welding process as a beginner. It can be a good solution to repair cast irons. It is not recommended for Malleable iron because it is likely to produce a wide heat affected zone of hard and brittle white iron.

Ad Improve Your Business ROI - Get A Better Deal On Welding Electrode. Pure nickel electrodes are suitable for cold welding of grey cast iron malleable cast iron and cast steel as well as for joining these materials to steel copper and copper alloys. Contact our experts now.

We ship worldwideCall us. The perfect angle for welding Cast Iron is a 90 angle. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

Clean the slag in between the welding process and peen each weld bead. Stocks in huge qty. The cast-iron electrodes are easy to use even for inexperienced welders.

Z308 cast iron welding electrode is a covered welding electrode with pure nickel core and graphitic coating for cast iron. This welding process can join two separate base materials together. Stoody Castweld 55 is used on worn cast iron parts requiring build up or joining but not needing tight dimensional control or machining.

Ferroweld AWS class ESt is a lower cost steel electrode. For welds where machining is not required and where the weld is expected to rust like the cast iron Lincoln Ferroweld stick electrode can be used. Stocks in huge qty.

Electrode having a nickel core wire for welding on grey cast iron with and without preheating. For multiple-pass welds SME A19 ferronickel welding electrode is suitable. Suitable to use in repair of machine frames machine housings machine parts and bearing blocks.

It can tolerate welding on castings that cannot be completely cleaned before welding. The Weld seam metal has excellent machinability and crack resistibility. Oxyacetylene welding is generally applied for Welding-cast-iron Gray and Ductile.

Nickel Alloy Electrodes supplier stockist. The disadvantage of MMA is the greater weld pool penetration and parent metal dilution but using electrode negative polarity. To Heat or not to Heat In general it is preferred to weld cast iron with preheat--and lots of it.

Stoody Castweld 57 consistently produces weld deposits which exceed the physical properties of standard 50Ni50Fe electrodes ENiFe-CI or ENiFe-CIA. Contact our experts now. Ad Improve Your Business ROI - Get A Better Deal On Welding Electrode.

Both AC and DC can be applied. MMA widely used in the fabrication and repair of cast iron because the intense high temperature arc enables higher welding speeds and lower preheat levels. Nickel Alloy Electrodes supplier stockist.

Nickel Iron Cast Iron Welding Electrode Welding Rod China Welding Electrode Welding Rod Made In China Com

Enife Ci Cast Iron Welding Electrode Tullyn Trading

Cast Iron Z408 Aws A5 15 Enife Cl Welding Rod Electrodes 2 5mm 3 2mm 4 0mm Buy Welding Electrode Cast Iron Welding Rod Aws A5 15 Enife Cl Product On Alibaba Com

1kg Cast Iron Welding Electrode Rods Welding Rods Aliexpress

Elektroda Las Besi Cor Kelas Atas Enife Ci Untuk Pengelasan Buy Kawat Las Welding Rod Las Cast Iron Rod Product On Alibaba Com

Pure Nickel Cast Iron Welding Rod Cast Iron Nickel Iron Electrode Nickel Copper Cast Iron Welding Rod 2 5mm 3 2mm 4 0mm Welding Rods Aliexpress

77 Non Cracking Cast Iron Welding Rod

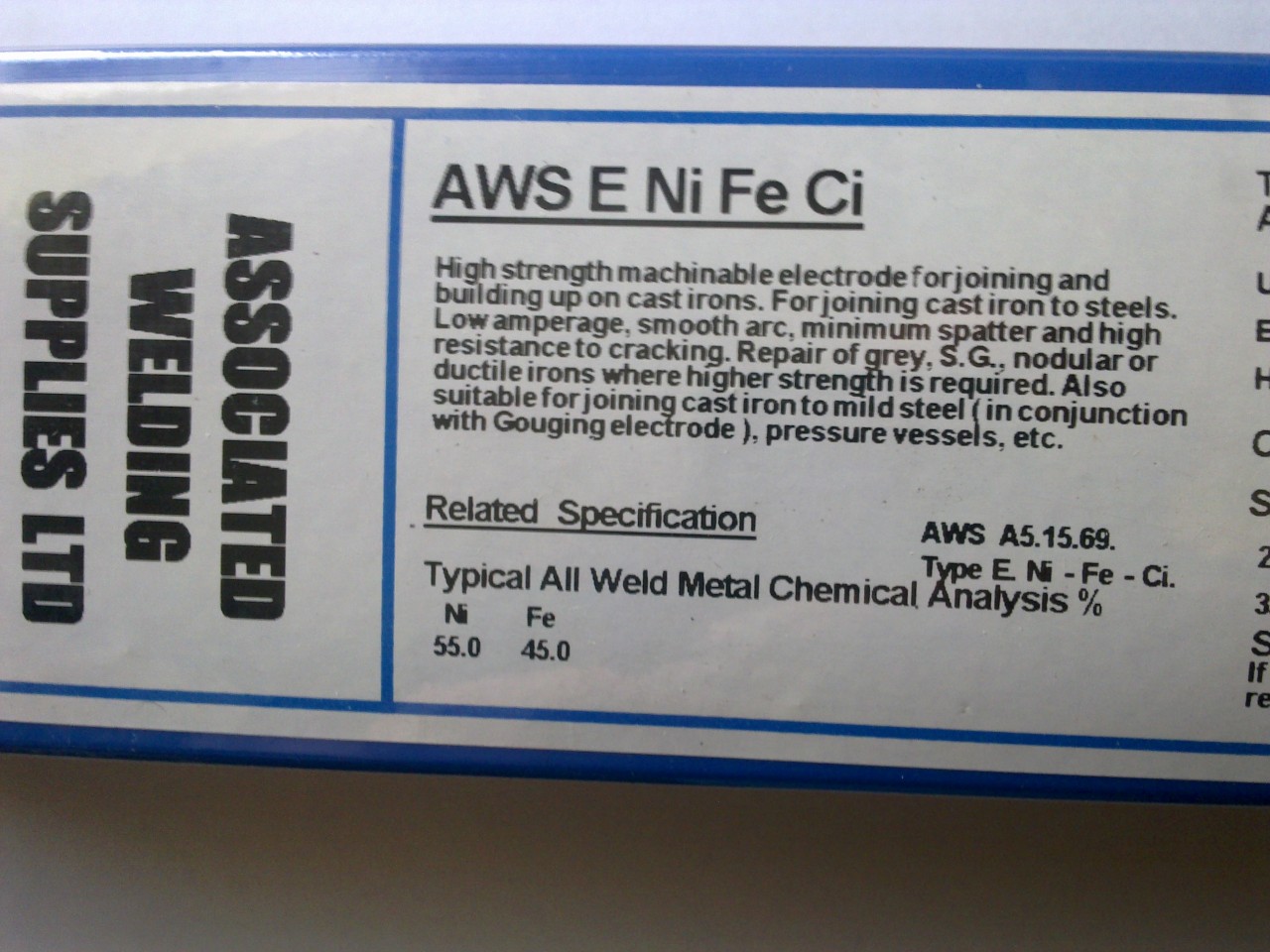

2 5mm Nife Cast Iron Electrodes X 1 Kilo Associated Welding Supplies Ltd

1kg Pure Nickel Cast Iron Welding Rod Cast Iron Nickel Iron Electrode Nickel Copper Cast Iron Welding Rod Welding Rod Rod Weldnickel Electrodes Aliexpress

0 comments:

Post a Comment