Stopping the welding process prematurely is. Crater pipe causes and prevention during welding.

Why Welds Crack Welding Answers

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding.

Welding meaning crater. A welding crater fill mechanism is provided with means for positioning welding guns in position for welding between weldment component moving relative to the welding guns and means to determine the length of the weld between the weldment components so that when such length of weld has been completed additional means move the welding guns so that the welding guns overlap at least a portion of the weld. What is a welding crater. Use of large electrode.

While they can occur with all arc welding processes they are more prevalent with processes that are capable of higher deposition rates and producing larger weld puddles ie. Crater occurs due to residual stress imposed by. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding.

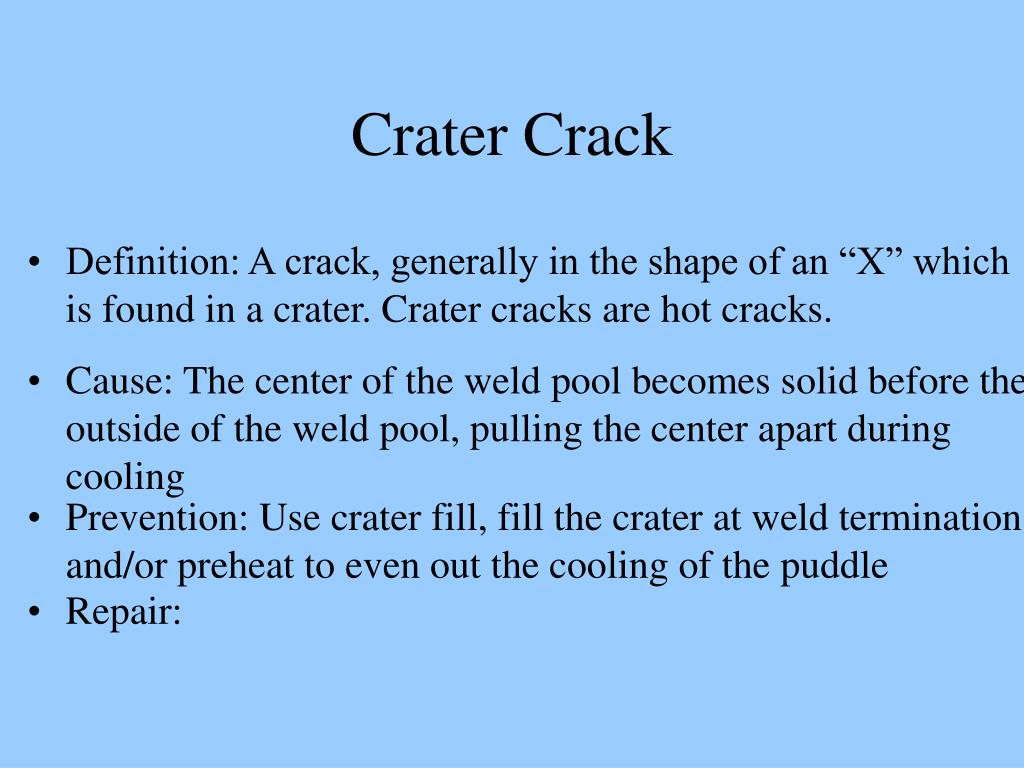

A crater pipe forms during the final solidified weld pool and is often associated with some gas porosity. The crater is a kind of crack which occurs when the welding arc is broken and molten metal is not available to fill the cavity. Causes of the crater.

Crater is welding flaw in the form of a depression on the face of weld metal due to improper arc manipulation of arc or improper termination of arc. Not to be confused with deformation which results immediately upon application of a stress. This crater results from the energy of the arc and the reduction of melted metal when it solidifies and cools.

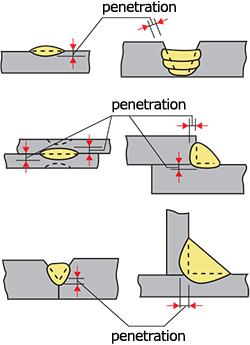

This causes a stress and then crack is formed. Welding methods that involve the melting of metal at the site of the joint necessarily are prone to shrinkage as the heated metal cools. Unless welding is performed with a very low current a concave dip called a crater occurs at the end of a weldment.

Consequently conditions which exaggerate the liquid to solid volume change will promote its formation. Creep The slow deformation for example elongation of a metal under prolonged stress. The size of each crater relates straightly to the welding current.

Again these weld crater shrinkage cavities are a naturally occurring phenomenon found in arc welding. Crater A depression in the weld face at the termination of a weld bead. This imperfection results from shrinkage on weld pool solidification.

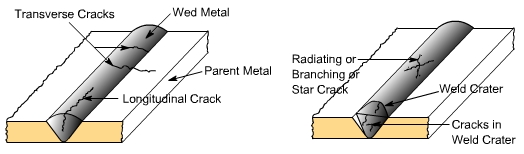

A definition of a crater in welding is an inadequate amount of molten metal used to fill the cavity leaving a thin section. Unless welding is performed with an extremely low current a concave dip termed as a crater occurs at the end of a weld-ment. These cracks usually start at a crater pipe and extend longitudinal in the crater.

First detected by a loud popping which can stop the welding process in extreme cases. Crater cracks are normally shallow hot cracks usually forming single or star cracks. Most often it is the result of encountering tiny pockets of oxidation inside or on the surface of the metal being welded.

A crater is a tiny explosion which will send droplets of molten metal in every direction. This crater results from the force of the arc and the contraction of melted metal when it cools and solidifies. However they may propagate into longitudinal weld cracks in the rest of the weld.

It occurs when the crater is not filled before the arc is broken which causes the outer edges to cool faster than the crater. The inadequate amount of molten metal gives a crater the appearance of a circular excavated hole.

Welding Defects Classification Causes And Remedies Welding Ndt

Welding References Education Center Kobelco Kobe Steel Ltd

7 Most Common Welding Defects Causes And Remedies Slv

7 Most Common Welding Defects Causes And Remedies Slv

What Are Weld Craters And Crater Cracks The Graduate Engineer

Ppt Defects And Discontinuities Powerpoint Presentation Free Download Id 1764968

7 Most Common Welding Defects Causes And Remedies Slv

0 comments:

Post a Comment