Welding for battery manufacturing requires unique technology and expertise working with metals and metal combinations which are not easy to weld. BATTERY ELECTRIC VEHICLES 2.

Nikita Baliarsingh Co Founder Coo Of Nexus Power On How Their Company Is Making Ev Batteries From Crop Residue And What Impact It Will Have On The Ev Market In 2021

The number of electric vehicles EVs in global circulation increased sixfold between 2013 and 2017 according to the International Energy Agency.

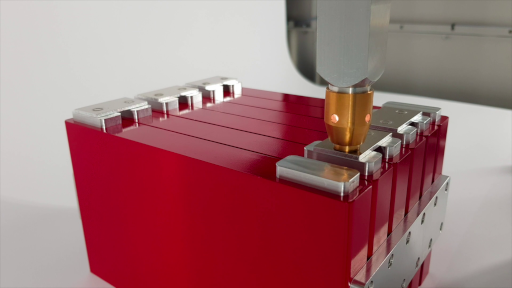

Laser welding batteries for electric vehicles. According to a multitude of press releases that cross our desk battery manufacturing is a hot market now with substantive growth led by accelerated demand from the electric vehicle EV industry. JOINING TECHNOLOGIES FOR BATTERIES 1 Ultrasonic Metal Welding 2 Resistance Welding 3 Laser Beam Welding 4 Wire-bonding 5 Mechanical Joining 4. Whether your company is developing bus bars battery and capacitor arrays or battery cases EB Industries has experience collaborating with customers to develop amazing solutions.

B Variation of spatial power modulation a left to right for CuSn6 on top and DC04 steel on the bottom resulting in smaller penetration depth for all applied. These batteries are located inside a case thats completely sealed. 5 Summary and Outlook A clear assignment of the battery system requirements to the respective components in the entire car enables the resolution of redundancies and enhances the production efficiency.

New Trends in Laser Beam Welding How automotive applications are driving the future of laser technologies Francesca Moglia and Antonio Raspa electric powertrain welding high current device welding battery cell assembly battery pack welding power control unit PCU assembly Fig1 Electric vehicle welding applications are the main drivers in. Of Li-ion based automotive battery packs make them an emerging alternative power source that are being increasingly used in electric vehicles EVs hybrid or plug-in hybrid electric vehicles HEVs or PHEVs 13. In the course of developing battery systems which consist of several hundred cells the energy efficiency still needs to be increased.

Lithium-ion batteries are preferred in electric and hybrid-electric vehicles due to their high energy density. Laser beam welding of battery application. Electric cars are battery-powered.

THE INDUSTRIAL LANDSCAPE 1 Cell. Welding techniques for welding batteries. Laser welding assists in the long term stability of the joint whilst maintaining good electrical contact.

At Adapt Laser we provide laser technology for pre welding treatment to clean the metal components for higher bond strength. All three methods are tried and proven to function in the production of battery applications. V 100 mms adjusted from.

LI-ION BATTERY CELLS MODULES AND PACKS 1 Formats of Li-ion Battery Cells 2 Battery Modules and Pack 3. As part of the AiF project MikroPuls Fraunhofer ILT is developing laser processes for the efficient contacting of battery cells pictured. A Different seam shapes on bus-bars welded to cylindrical battery cells Kundrat and Alexy 2018.

In addition our lasers are used to completely seal the joints. Often these vehicles are exposed to different driving conditions having a huge impact on the energy consumption 4. Among all available laser technologies disk lasers with their insensitivity to back reflection are an ideal choice for welding highly reflective materials such as aluminum and copper.

The compared techniques are resistance spot welding laser beam welding and ultrasonic welding. Alone about 760000 EVs. For the production of Li-ion batteries and so much more laser welding is a popular joint process due to its high speed small heat-affected zone and low occurrence of deformation.

For hybrid automobile and high-tech space-based batteries Fiber Lasers can be used to weld the many thin plates in the battery and weld or braze components together to optimise the energy per unit volume. In the course of developing high performance Laser beam welding of electrical contacts of lithium-ion batteries for electric- and hybrid-electric vehicles SpringerLink. Laser welding technology for dissimilar metals helps reduce EV battery energy loss.

The 500-W and 1000-W lasers developed by NUBURU Inc. Lithium-ion batteries are preferred in electric and hybrid-electric vehicles due to their high energy density. Laser-welded copper connectors on cylindrical cells.

Were developed for welding copper and copper alloys. P 170 W. A promising measure to reduce electrical losses is the contact between cell terminal and cell connector.

The laser has been tested for its ability to perform many of the welds commonly found in batteries and electric vehicles. The performance was evaluated in terms of numerous factors such as production cost degree of automation and weld quality. Glass to metal feed-through pre-forms can also be Laser welded into the battery assembly to provide a hermetic package.

The production time of the laser-welded low-cost battery pack housing is therefore 3 min and 20 s and has been reduced by 91 compared to the riveted version with 38 min. Laser welding techniques using mixed red and green lasers have been developed for welding copper-copper and copper-aluminium lap joints for car battery electrodes.

Building Batteries Welding Productivity

Sunkko 737g Battery Spot Welder 1 5kw Led Light Spot Welding Machine For 18650 Battery Pack Spot Welder Spot Welding Machine Spot Welding

How Laser Technologies Are Boosting E Mobility E Mobility Technology

Service Disconnect Plug Energy Storage High Voltage Fuel Cell

Sunstone Welders Micro Welding Education Battery Welding Lithium Batteries

Pin By Matoledaniel On Shielded Metal Arc Welding Welding Projects Shielded Metal Arc Welding Spot Welding Machine

Battery Sorting And Sticking Machine With Battery Collection Box Battery Collection Box Sorting

Bmw Group Thailand Begins Local Assembly Of High Voltage Batteries For Bmw Plug In Hybrid Vehicles Bmwfiend Com Hybrid Car High Voltage Bmw

Charged Evs Smart Welding Battery Packs Battery Pack Energy Storage Battery

0 comments:

Post a Comment