We will additionally put images in the comments of how our package looks like compared to our competitors packages. I would braze it.

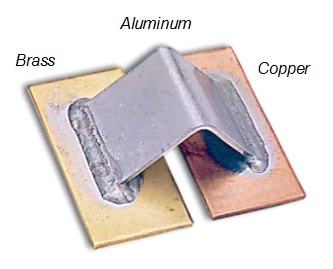

Aluminum And Zamac Welding Malloy

Use an oxyacetylene torch in most instances to weld brass.

Welding broken brass. Start your torch or welder and bring the heat close to the surface. Before welding the brass find out the zinc content of the material you are going to weld because zinc has a lower melting point than copper. Combine that with the fact that brass is very thermally conductive and requires quite a bit of heat input to weld and you have an arc that tries to vaporize the zinc.

If the check valves are still good you can scavenge the valves and hose barbs and get just the new body for like 15 or if its a 2-way manifold use a 7 Y adapter. Below are some of the items youll need gather up before you learn how to weld brass to brass. Since the oxygen and acetylene are stored individually you have more control over the torchs flame.

Pipe and Plate Alloy Stainless Aluminum Bronze Brass Cast Steel Fabrication Imbeds Structural Steel Stairs Hand Railing Brackets Frames Nursery Carts Utility Trailers. When the zinc boils it will often jump onto your electrode. They are also easy to melt.

You can do it yourself with little hassle and minimal knowledge of the subject. Very slightly just a little extra lick of blue. A broken weld doesnt mean its the end of the road for your metal component.

30 is for the manifold with the check valves and everything. The next most important part of soldering brass is to make sure it is clean. By OBEWAN Date 03-12-2013 1650 Edited 03-13-2013 0642.

The oxygen and acetylene gases are stored separately but are mixed during welding. Replace it not repair. This metal tends to have a low melting point which affects the way you work with and weld the material.

Welding brass is very easy because you can use soldering materials to complete your weld. Heat the welding surface. Easy Welding Rods do not bend they break.

Zinc has a really low melting point. You dont have to be a commercial welder to get your brass back together. You should use either a braze-welding flux or one that is specially created for oxyacetylene welding.

Because of its low melting point you should be able to weld the brass together within a couple of seconds. Ideally you should be able to weld brass with soldering MIG or TIG welding tools. Pad weldingPlate welding test plate Angle is 90 and the direction of the welding Angle is 70 80 the welding current is 120 a broken arc welding method the electrode in the welding groove of the transverse swing slightly will preheat electrode when the welding in the welding of the tail a little push rod hear the sound of the yue said.

For repair purposes bronze or brass should be used for the welding filler rod-for foundries or in manufacturing where the weld must be practically the same color and the same material as the metal more judgment is necessary in the choice of the rod with a view of replacing by means. First you will need to mix a flux with water until it creates a paste. Posted by qvantamon at 255 PM on May 4 2010.

Here is how to tell the original Easy Welding Rods from the competitors rods that are sold with similar names but dont work. Brass is a difficult metal to weld because it contains zinc. Brass will often have a protective covering to prevent it from tarnishing.

The reason tig welding brass is difficult is because of the zinc. The metal will have a higher melting point than the filler rods but still avoid pointing the heat. If have a broken piece of brass you can spot weld it with a tungsten inert gas welder.

Bill Brown Welding has a 6GR Certification and specializes in complex fabrication and repairs. Founded in 1963 our family-owned shop has extensive experience in the repair of. This will cause you to have to stop grind your tungsten and continue working.

Of the material in the welding rod those metals burnt out of the line of welding by the flame. Your best bet would be to cut a second piece of brass and solder it over the damaged piece. Paint this onto the brass surfaces that you intend to weld.

Brass is a fairly broad term so I recommend that you take a closer look at just exactly what brass you are working with. The technique of overhand welding. We do all types of repairs large and small.

Cleaning the brass removes. Get it restored to its original state and functionality with precision welding repair from Acme Brass Aluminum Manufacturing. A zinc coating requires less heat than copper.

Welding brass to stainless. By bozaktwo1 Date 03-12-2013 1641. Make sure to clean it really well and make sure you use the right flux and a slightly carbeurizing flame.

This must be removed thoroughly before you begin to solder.

7 Steps For Welding Brass To Brass Weldingboss Com

How To Solder Braze And Weld Stainless Steel To Copper In 5 Easy Steps Learn To Moonshine

Brass Repair Made Easy And Copper Bronze Aluminum In Any Combination With Super Alloy 1 Youtube

Lazera Lt Laser Welding And Repair

How To Weld Brass Using The Most Effective Welding Process

Brass To Brass Follow Us Welderzworld Photo By Theonezim Welderzworld Weld Smaw Fabshop Tig Fab101 F Welding Art Welding Design Tig Welding Aluminum

0 comments:

Post a Comment