A frequently-used process with a continuously-fed consumable electrode and a blanket of fusible flux which becomes conductive when molten providing a current path between the part and the electrode. If youre MIG welding check the following.

Causes Of Weld Spatter How To Reduce It Weld Guru

Understanding polarity is essential as it can impact everything from the welding machine setup to the type of electrode being used.

Welding spatter meaning. Firstly what is spatter. High Welding current can cause this defect. The issue with weld spatter is that it can harm your skin.

When these drops fly out as you weld some tend to stick on the equipment and work pieces. According to the grammatical definition spattering means scattering small particles of a particular substance. Spatter balls also stick to welding equipment and tools.

The flux also helps prevent spatter and sparks while suppressing fumes and ultraviolet radiation. Spatter is literally your weld wire blowing out and throwing equipment spend on the floor or on the part to grind out. A proper weld schedule is always important to efficiently apply the proper force bring the projections up to temperature and forge the weld with the proper fast.

How to Remove Grinding Sparks from Glass The Process If youre able to be proactive and protect your glass that is really the best solution. The longer the arc the more chances of getting this defect. The welding spatter defaces your work blocks up your torch head and can cause a short circuit when the weld spatter stuffs up your nozzle and contact tip.

It can also have quite an impact on the results from your weld. Weld spatters stick on the area youre working on. It can cause burns as it goes through the clothes and gets to the skin most especially if not wearing welding sleeves that are OSHA recommended.

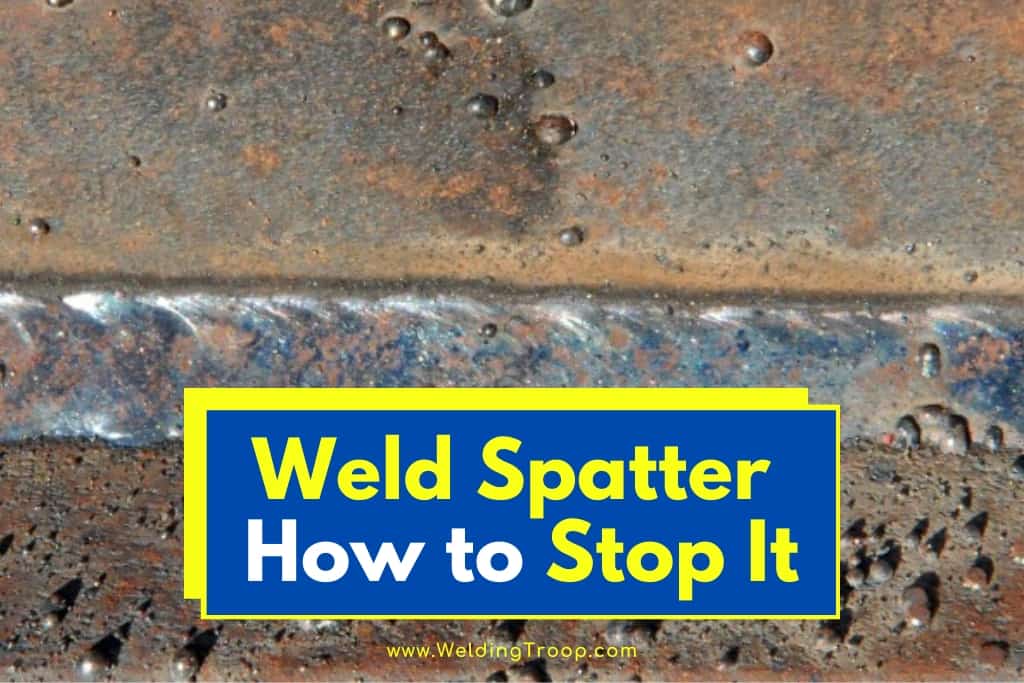

While welding you might have noticed molten metal balls ejected into the air that burned your skin or froze on your welding tools. These are referred to as spatter. These small bits of hot material may fly and fall on the workbench or on the floor while others may stick to the base material or any surrounding metallic material.

The concept of polarity in welding is essentially the direction of your electrical current flow from your welding power source to the piece you are working with. The primary reason being safety. Definition - What does Weld Spatter mean.

If weld anything with studs or threaded studs spatter becomes a. Spatter balls can burn through welders clothing and skin. During welding you may realize that some small drops tend to fly and land on the surface.

Weld spatter consists of droplets of molten metal or non-metallic material that are scattered or splashed during the welding process. Generally the most common causes of excessive spatter is a problem with shielding gas power or wire speed. Unprotected glass and welding means you will probably get grinding sparks into the glass.

If the weld head sticks or is slow the weld strength will suffer and the strength will be low or in an extreme case no weld and flash expulsion or spatter could result. Thankfully there are processes you can follow to remove the grinding sparks from the glass and save your work. Spatter Build up On Nozzle And Contact Tip When this welding spatter prevents your wire from feeding out and or blocks your shielding gas it can cause your weld to fail unless the spatter.

In welding spatter is a defect or a side-effect. When some metal drops are expelled from the weld and remain stuck to the surface then this defect is known as Spatter. Spatter is a problem especially for a professional welder when welding for several reasons.

Improper gas shielded may also cause this defect. Welding jargon refers to these small metal blobs as spatters.

Weld Failure Of Porosity Residual Stress Crack Undercut Spatter Techminy

On The Surface Welding Productivity

7 Most Common Welding Defects Causes And Remedies Slv

What Is Spatter In Welding Quora

The Problem With Weld Spatter And How To Stop It Welding Troop

What Is Welding Defects Types Causes And Remedies The Welding Master

7 Causes Of Spatter And How To Eliminate It Welding Answers

What Is Spatter In Welding Quora

Welding Defects And Discontinuities Ppt Video Online Download

0 comments:

Post a Comment