For higher flame temperature a mixture of a gaseous fuel and industrially pure oxygen is used. Being an owner of a welding yard I have vast experience of almost all welding types.

Gas Shielded Arc Welding Processes Tig Mig Mag Openlearn Open University

Commonly used MIGTIG Welding Gas Cylinders.

Welding gas meaning. What Is A Shielding Gas In Welding. What Is The Most Common Gas Used In Welding. Oxygen is usually kept in steel containers under a pressure of 15 meganewtons per sq.

Gas welding is a type of liquid state welding process in which fuel gases burns to generate heat. In this welding process mostly oxy-acetylene gas is used as a working fuel gas. Youre looking for two sets of numbers separated by a dash.

How To Read Your Gas Cylinder Date Stamp Quick Overview. Welding is a highly technical process with numerous types and techniques that only skilled personnel are able to understand and practice. That is the reason shielding gas is extremely important during the process of MIG welding as these inert gases provide a.

Argon isnt the only type of gas that is used for welding processes. Gas tungsten arc welding GTAW also known as tungsten inert gas TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weldThe weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas argon or heliumA filler metal is normally used though some welds known as autogenous welds or. Your gas cylinder was last tested in July 2016.

Gas-welding process involves the utilization of a centered and outrageous high-temperature burst which is created by the consumption of gas or gases blend Ogundimu 2017. Argon is the most common gas used in MIG or TIG welding because it provides cleaner results but some use an ArgonCO2 mix or just CO2 instead. You can hear people call them gas MIG welders because of that are the most common shielding gases in welding but other.

Gas is the main component in MIG Metal Inert Gas welding as these inert gases wont react with the welding bead where non-inert gases like oxygen can react with outside air and cause the bead to become highly porosity. This heat is further used to melt interface surfaces of welding plates which are held together to form a joint. The most common gas for welders is an Argon and CO 2 mix because it is low cost and gives good results under most conditions.

The first real attempt to adopt welding processes on a wide scale was made during World War I. MIG Metal Inert Gas welding is a welding process in which an electric arc forms between a consumable wire electrode and the work piece. A process of welding through the spot melting of a metal by the flame of a gas-fed welding torch.

This heat is used to melt interface surfaces of welding plates which are held together to form a joint. I have seen most of the hobby welders or house owners use 40 80 or 125 cf tanks of Argon or MIG gas mixture throughout my career. Among these types Metal Inert Gas MIG a type of Arc welding is the most common.

Gas welding is a process in which two or more parts of the metal are mixed or united using heat transmitted by the heat produced by the reaction of oxygen and fuel gas. Definition of Gas Welding. This engaged blast is then used to condense the workpieces to be joined.

Gas welding arc welding and resistance welding all appeared at the end of the 19th century. By 1916 the oxyacetylene process was well developed and the welding techniques employed then are still used. Gas welding is accomplished by melting the edges or surfaces to be joined by gas flame and allowing the molten metal to flow together thus forming a solid continuous joint upon cooling.

Argon and CO 2 mostly used in with MIG welder. AR Argon ARCO2 Mix and CO2 Carbon Dioxide Gas. If the second set of numbers after the dash says 16.

This process can be done with or without the help of filler material. There are many types of welding namely Arc Friction Electron Beam Laser and Resistance welding. Shielding gas would describe the application to a variety of processes where the function of the gas is to protect the weld pool from atmospheric contamination during the welding process and in many instances to aid in the heat transfer more so or less and weld penetration characteristics and profile of the applied weld.

This process is particularly suitable for joining metal. If the first set says 07. Look down the side of your gas cylinder.

Mig Vs Tig Welding Types Materials And Applications A Guide

Gas Shielded Arc Welding Processes Tig Mig Mag Openlearn Open University

Oxy Fuel Welding Or Gas Welding Welding Ndt

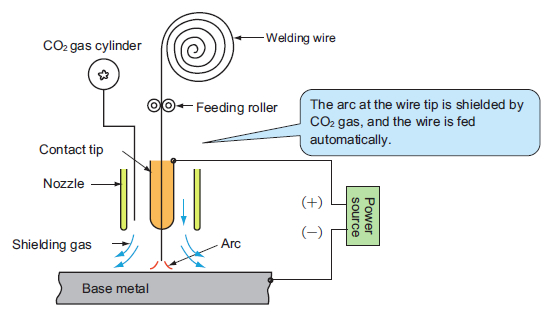

Fundamentals Of Co2 Arc Welding Education Center Kobelco Kobe Steel Ltd

Mig Vs Tig Welding Types Materials And Applications A Guide

Mag Welding Metal Active Gas Welding Kovinc D O O

Gas Welding Oxy Acetylene Gas Welding Tamil Youtube

Types Of Welding Gases And Their Purpose Gz Industrial Supplies

Gas Welding Chapter Ppt Download

0 comments:

Post a Comment