In the case of electron beam welding EBW the study is performed by offsetting the beam toward both steel and copper side. This offset shows on the reference line as well.

Schematic Illustration Of The Laser Offset Welding Low Technique Download Scientific Diagram

Investigated the weld strength in the offset range 03 to 15 mm and the optimum range of 02 to 10 mm for steel and copper respectively.

Welding beam offset. Maximum of 18 inches. The bottom plate is stitch welded to the beam and is often offset to one side so that the brickwork is sufficiently supported. The laser beam provides a concentrated heat source focused to the cavity between the two metal pieces to be joined.

Argon gas with the purity of 9999 was applied as a shielding gas with total flow of 20 Lmin at top of the joint. The first AgAI weld ed with the beam offset to fuse only the Al and the second Fe18Cr8NiNi15Cr7Fe with the beam on the joint. Base plate To ensure longevity and stability it is essential to leave a gap of around 20 30 mm between the concrete and the steel plate which can be achieved using shims and wedges.

The process is frequently used in high volume applications using automation as in the automotive industry. Stress in a fillet weld. Base metal of the AgCu20Ni weld at a few locations up to 50 im depth.

11 Schematic for illustration of beam offset position in electron beam welding of Ti55TA15 weld. The nature of welding is the primary cause of distortion or bending during the welding process. Length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length.

It could be staggered in either direction on the reference line. Correction of misalignment must not cause a slope greater than 12 inches over 12. Laser Beam Welding Titanium T-6AI-4V Beta-C Dissimilar Alloys GTAW CO Laser Laser Beam Location Fusion Zone Comp.

The results showed that the weld appearance improved with the increase of the offset. The effective area shall be the ef-fective weld length multiplied by the effective throat. The alloy contains the beta-isomorphous elements V and Mo and the sluggish beta-eutec-toid elemen t Cr a levels which depress.

Offset from theoretical alignment must not exceed 10 percent the thickness of the thinner part joined. Molten Ag penetrated the Cu20Ni B. Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

Laser Beam Offset cellent combinations of strength ductil ity and fracture toughness. Venants torsion is applied to the section and the rate. Thin walled open section made of rectangular elements In many cases only uniform or St.

Parameters used in laser beam offset welding of dissimilar MoTi joint. To achieve this while still keeping the piece sizes small enough for transportation short stubs of the beam section are welded to the columns. BEAMS SUBJECTED TO BENDING AND TORSION-I 1c 3 i J b 3 1 i ti in which bi and ti are length and thickness respectively of any element of the section.

Specimen Power W Welding Speed mmin Defocusing Amount mm. Thermatools beam welding lines provide a benefit to design engineers and manufactures by allowing greater customization of beams. The intention with shop welded construction is to ensure that the main beam-to-column connections are made in a factory environment and can be full strength rigid joints.

Bi t i Fig. The connection of the stub to the rest of the beam is normally made with a bolted cover plate splice. Cross-sectional microstructure of the BMs of a Molybdenum and b Titanium.

It is this localized heating and cooling that distorts the metal parts as you weld. The welds will be placed on both sides of the joint but it will be offset with one another. The welding parameters were.

In the AgFe18Cr8Ni weld a layer of about 20 m thick of steel. EBW of dissimilar metals can adopt various welding methods including fusion welding and re-melt deposit welding. Along the edge of a connected part less than ¼inch thick the maximum fillet weld size w equals the plate thickness For other values of plate thickness t the maximum weld size is t 116 in.

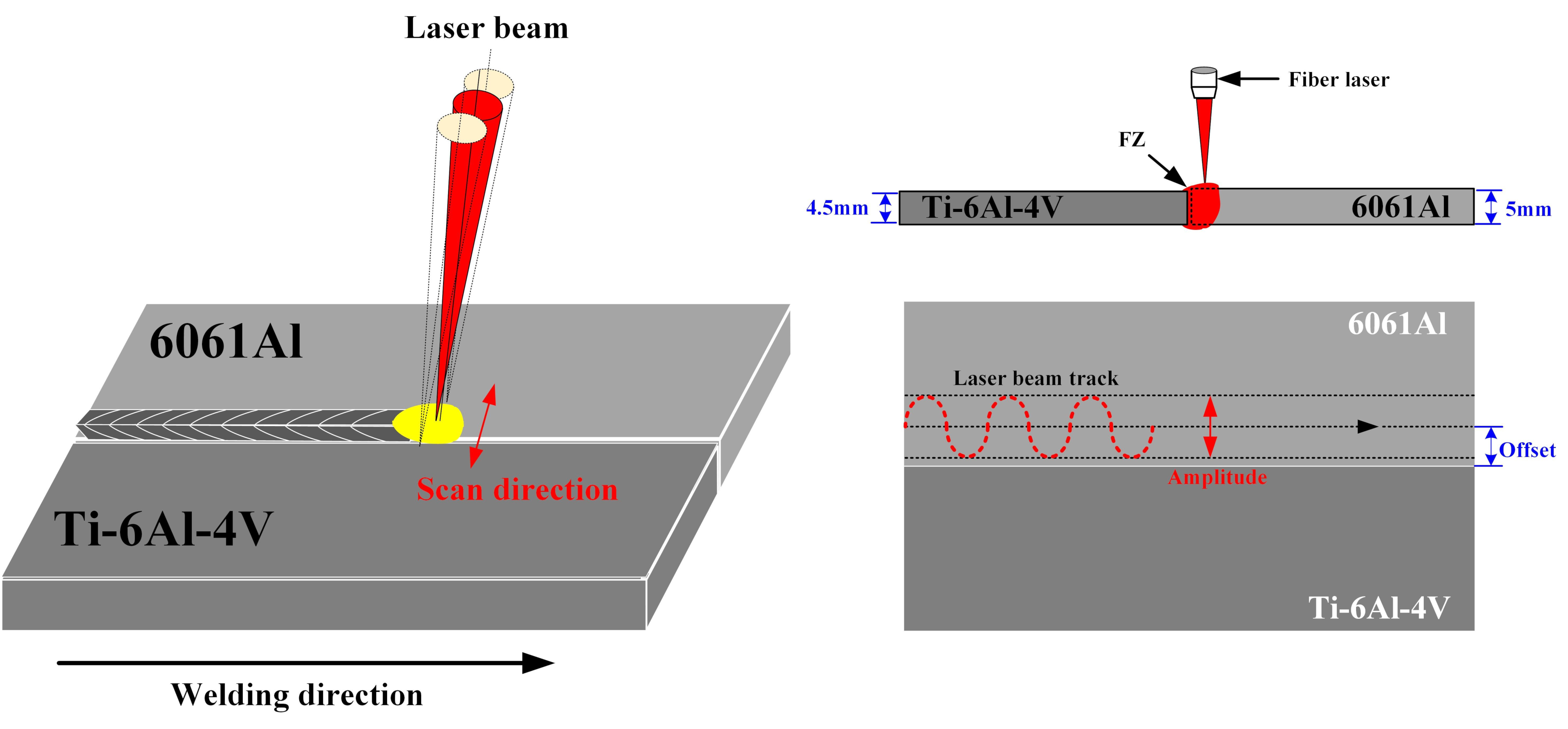

The effects of laser beam offset on the laser dissimilar joint of pure molybdenum to pure titanium were analyzed in terms of microstructure chemical composition microhardness and tensile behavior. The maximum size of a fillet weld is as follows. Welding needs high temperatures localized in a very small area to allow the metal to fuse.

The schematic illustration of a laser beam offset welding and b spot size and position at different offsets. But for focus spot on the side of copper or stainless steel another re-melt deposit welding butt joint will form. Offset beams in T and Z shapes are now easily produced to fit exact geometry load and length requirements.

By adjusting beam offset when focus spot is on the middle line of the docking a normal butt weld is formed. Laser beam power of 576 W defocusing distance of 5 mm welding speed of 650 mmmin. The LBW and EBW processes however are expensive along with.

Carefully align parts joined by groove welds. Dimensions of these welds must be specified on both sides of the reference line. The actual offset of the beam in welding is usually not straightforward and requires a feedback loop photodetector in the case of LBW for detecting position of the beam.

Schematic Illustration Of The Laser Offset Welding Low Technique Download Scientific Diagram

Schematic Illustration Of Laser Keyhole Welding Of Al Steel Butt Download Scientific Diagram

Materials Free Full Text Effect Of Laser Beam Oscillation On Laser Welding Brazing Of Ti Al Dissimilar Metals Html

Cross Sections Of Laser Lap Welding T Joints At Different Offset Size Download Scientific Diagram

Schematic Illustration Of Laser Keyhole Welding Of Al Steel Butt Download Scientific Diagram

A Dimensions Of The Welded Coupons B Position Of A Laser Beam With Download Scientific Diagram

Metals Free Full Text The Effect Of Laser Offset Welding On Microstructure And Mechanical Properties Of 301l To Ta2 With And Without Cu Intermediate Layer Html

Metals Free Full Text Effect Of Disk Laser Beam Offset On The Microstructure And Mechanical Properties Of Copper Aisi 304 Stainless Steel Dissimilar Metals Joints Html

Https Www Sciencedirect Com Science Article Pii S2351978919310182 Pdf Md5 06726d793855b0d76dd90ca44ba150e2 Pid 1 S2 0 S2351978919310182 Main Pdf

0 comments:

Post a Comment