It is not a welded cast iron. Selecting the right rod.

Model T Ford Forum Cast Iron Oxy Acet Welding

Amount of heat always low and slow.

How to oxy weld cast iron. More on brazing later. Once you choose metal then you need to select the process using to weld it. Critical steps for Welding Cast Iron.

Oxyacetylene welding is one of the most well established methods of joining cast iron. Brazing isnt really welding as it doesnt fuse the metal as a weld does. So its important to understand the reality and the difficulty to adopt stick welding to weld cast iron.

Preparation beveling or drilling holds before and after cracks cleaning the surface. Choose a pre-heat temperature. Slowly pull the trigger to the cast iron until there is a pool of molten metal.

Welding cast iron works much better with repair jobs like cracked parts or when you drilled a hole in the wrong place and you need to fill it in. In oxy acetylene welding you also use an electrode. The head is pre-heated to approximately 1800 degrees where it was Fusion Welded using Oxy-Acetylene and bare cast iron rod.

Masses agree to preheat as a better choice while few goes with minimal heat or cold weld. To weld cast iron stick welding is the preferred method and you dont need any Oxy acetylene torch for it. You can choose either cast iron or copper zinc electrodes for welding cast iron using this technique.

However the arc is generator not by the current but by the energy provided by the oxy-acetylene torch. Use of a gas flame to heat the casting to its melting point is time consuming and can lead to surface oxidation but the high preheat of the base metal and the low cooling rate which results ensure that formation of hard phases such as martensite in the HAZ. It is less brittle because of microstructural differences.

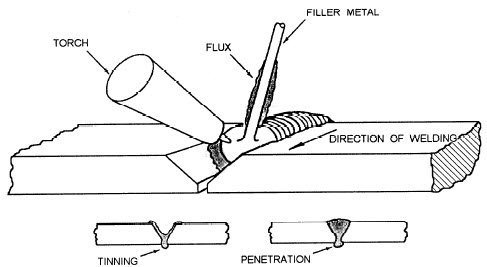

At times it may be necessary to break the oxide by stirring the molten iron with the rod and if the metal is very dirty by pulling it out of the line of welding by means of the rod. Other options you can use is oxy-acetylene welding which is commonly used in the welding of cast iron. If theres a crack that youre trying to repair you need to properly.

Because unappropriated steps can give it more cracks in the pieces. Oxy-acetylene welding is another option frequently used to weld cast iron. This technique is commonly used to correct cracks on cast iron items.

To weld cast iron start by preheating the section youll be working to a temperature between 500 to 1200 degrees F so that its stable enough to work with. Its advantage is that it has minimum impact on the base metal. This is after the Fusion Welding and shows the weld rough ground to conform to the original casting.

Select a suitable welding technique. Raise the temperature of the broken part of cast iron. Stick welding is a complex welding method.

The three important considerations when welding are. Pull the electrode on the steel not cast iron. Use the flux sparingly-never throwing it in with the hands-the amount picked up by the hot welding rod is sufficient at all times.

Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it. Welding cast iron has two schools of thought one is hot and the other is cold welding. Preheating or cold weld.

Then fix any cracks or rips in the. Place cast iron and steel in the p osition where they are welded. Clean the whole casting.

A common method that is used for joining cast iron parts together is brazing. Unlike the traditional welding technique used to repair metal items brazing uses minimal heat to fix your cast iron pieces. After grinding brush the surface of joining with stainless-steel It makes all the debris cleanout and now its ready for the next step.

Generally welding two pieces of iron together is a bad idea youll be better off with brazing. The head is all finished. It helps keep the extreme heat and and cool-down of welding methods to a minimum and is simpler to keep track of the temps of your components with this method.

This head has a cracked ear. Preheating and slow cooling of the component is the crux for the cast iron welding procedure. This shows the crack prepped for welding.

The following is a step by step guideline on how you can fix cracked cast iron. Extend the welding electrode by pulling the welding gun to approximately 14 inch from the welding nozzle. By providing heat from the heat gun.

As a gradual increase of temperature required an oven recommended before applying its heat gun. Welding Cast Iron Requires Lower Heat and Small Beads 1 At A Time to Avoid Cracking.

Stick Welding Cast Iron Repair Using 7018 Welding Rods

Cast Iron Repair Oxy Acetylene Welding

Cast Iron Welding Repair Using Flux Core Wire

Cast Iron Gas Welding Using Cast Iron Filler Rod

Stick Welding Cast Iron Repair With 6013 Youtube

Cast Iron Oxy Acetylene Welding Rod Gas Welding Accessories Amazon Com

0 comments:

Post a Comment